- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

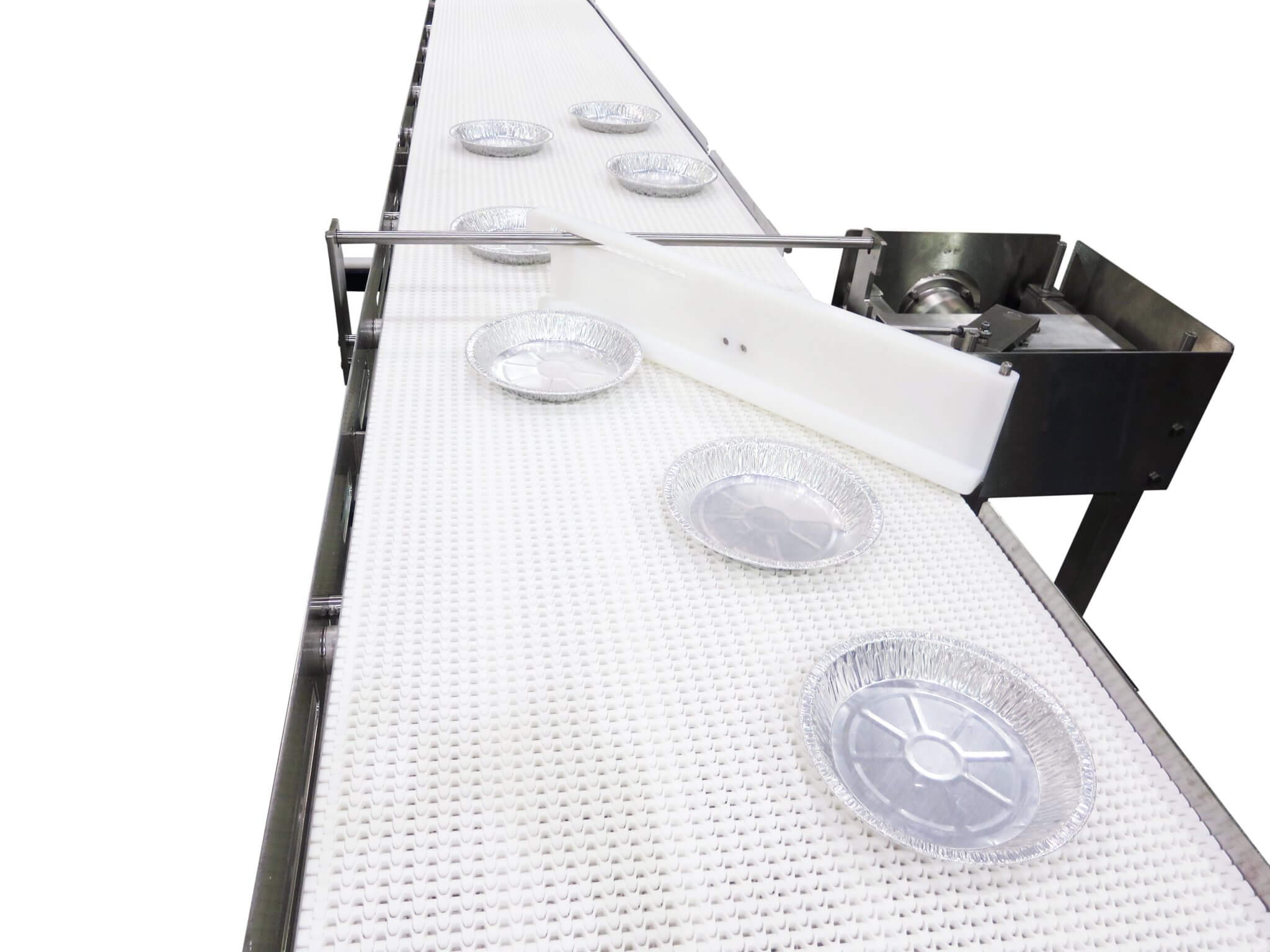

Baking & Confectionery Conveyors

Benefits of Baking and Confectionery Conveyors

Dorner has experience handling a variety of baking and confectionery products such as:

- Bread & Raw Dough

- Cookies, Donuts & Pastries

- Bulk Dry Ingredients

- Chocolates

- Gummies & Candies

- Chips & Rice Cakes

AND MORE!

Our line of custom designed sanitary conveyors are designed with food safety in mind and are ideal for applications such as:

- Elevating bulk products

- Grouping or spacing product for the next phase of the production line

- Merging or separating product lines

- Cooling, heating or draining

AquaGard® Series Conveyors

- Solid UHMW wear strips located in welded cross members for durable belt support

- Frame constructed of TIG welded 304 stainless steel

- Open design with minimal horizontal surfaces

- Low-profile frame and flexible belt options

AquaPruf® Series Conveyor

- Tip-up, tool-less pulleys and belt lifters for easy access for cleaning

- Rounded cross members to eliminate horizontal edges

- Solid UHMW wear strips for quick drainage and easy cleaning

- V-guided belt tracking

Engineered Solutions

At Dorner we recognize that our standard conveyor solutions aren’t always right for everyone. Our Engineered Solutions Group specializes in designing and implementing custom solutions for our customers. Our team of engineers will work with you to make sure that you get a quality conveyor system that fits your specific needs. In the food industry especially where each application differs greatly we are able to custom design a solution to fit your unique needs. Check out this blog post about a custom solution we created for a chocolate candy maker that made sure their line was running smoothly and efficiently.

Baking & Confectionery Conveyors

AquaPruf Conveyors

- Tool-less disassembly. Cleaning prep in under a minute, complete disassembly in less than 3 minutes

- Optional frame cut-outs and belt lifters for continuous access to inside of the conveyor

- Tip-up tails allow for quick release of belt tension

- Continuous TIG-welded 304 stainless steel frame

- Spiral cam belt tensioning with patent pending thread-less design

- Patented sprocket alignment key

- Gearless, oil-free iDrive2 sanitary motorized roller

AquaPruf Ultimate Conveyors

AquaGard LP Conveyors

- Loads up to 50 lbs. (22.7 kg)

- Belt speeds up to 246 ft./min (75 m/min)

- Belt widths: 2.7 in to 18 in (70 mm to 457 mm)

- Conveyor lengths: 19.7 in to 18 ft. (500 mm to 5485 mm)

- Complete 300 series stainless steel construction with #4 finish frames

- 1.25 in diameter drive pulley turns approximately 4.2 in (107 mm) of belt per revolution

- 1.5 in (38 mm) bottom of frame to top of belt

- Stainless steel bearings with FDA H2 food grade grease

- Washdown rated gearmotors and controls

AquaGard GT Conveyors

- Best for: packaging, bottling, dry food processing, part handling, long lengths, accumulation and buffering

- Smooth frame design for ease of cleaning

- Capable of multiple curves as well as inclines and declines on a single conveyor

- Bolt together construction for modularity and future add-ons

- Innovative transfer options

- Powered transfers

- Standard tails side to side transfer

- Side transfer modules

FlexMove Stainless Conveyors

- Stainless Steel Construction is ideal for corrosion resistant applications or packaging lines

- Provides capability for vertical incline with minimal floor space

- Features modular framing for future add-on capability and production line changes

- FlexMove Solutions eliminates unnecessary cutting, inventory and waste

AquaGard 7350 Conveyors

- Rugged and Durable Design

- 304 Stainless Steel frame features open design with minimal horizontal surfaces

- Designed for wipe down and low pressure wash-down with non-caustic chemicals

- V-guided belt tracking on belted models

- Tip-up tails for access inside the conveyor for cleaning and maintenance

- Safest chain in the industry with chain openings less than 4 mm even on curves

- Unique chain design virtually eliminates friction providing capacity for up to 4 curves on a single conveyor

Sanitary Roller Conveyors

- Frame is constructed of continuous TIG welded 304 stainless steel for durability in tough applications

- Integral 1” high side for product containment or low side for maximum flexibility

- Solid Acetal rollers and guides simply lift out of UHMW guide for quick for access to frame during cleaning

- Hollow Tube spring loaded roller can be removed quickly for access to frame during cleaning

- Optional welded end stop available for durability

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy